The Importance of Precision in Optical Fibre Diameter Analyser for High-Quality Manufacturing

The Importance of Precision in Optical Fibre Diameter Analyser for High-Quality Manufacturing

Blog Article

Discover the Significance of an Optical Fibre Diameter Analyser for Accuracy Measurements

The precision of optical Fibre measurements is vital in the telecom market, where also the tiniest inconsistency in Diameter can lead to considerable signal deterioration. An optical Fibre Diameter analyser offers as a critical tool to make sure these dimensions are precise and constant, thus enhancing overall system efficiency.

Recognizing Optical Fibre Diameter

Understanding the Diameter of optical fibres is crucial for making certain ideal efficiency in telecommunications and data transmission applications. Optical fibres typically come in 2 primary categories: multi-mode and single-mode, each with distinctive Diameter specs.

Standardization in Diameter specs makes sure compatibility in between various Fibre kinds and ports, decreasing the risk of system failures. As telecoms innovation proceeds to progress, the demand for trusted optical Fibre Diameter analysis comes to be significantly extremely important, underscoring the importance of employing advanced dimension devices and techniques to keep top notch interaction networks.

Advantages of Accurate Measurements

Accurate measurements of optical Fibre Diameter are critical for maximizing network performance and reliability. The integrity of optical signals is straight affected by the uniformity and precision of Fibre sizes, as inconsistencies can result in increased depletion and signal destruction. By making sure that the Diameter of optical fibres is consistently gauged within defined tolerances, drivers can lessen losses and improve overall transmission top quality.

Moreover, accurate Diameter evaluations contribute to reliable Fibre splicing and connectorization. Dissimilar diameters can result in inadequate coupling performance, causing enhanced insertion losses. This accuracy is especially important in high-speed networks, where even small discrepancies can have considerable influences on data transmission rates.

Additionally, maintaining rigorous standards for optical Fibre dimensions aids in conformity with market regulations, making certain that products fulfill required requirements. optical fibre diameter analyser. This not only bolsters customer confidence however also improves the reputation of makers and company in the affordable telecommunications landscape

Inevitably, the benefits of precise dimensions expand beyond prompt performance gains; they promote lasting reliability and toughness of network infrastructure, paving the means for future advancements in optical communication innovation.

Applications in Telecommunications

The applications of optical Fibre Diameter analysers in telecoms are crucial for ensuring optimal network performance and effectiveness. optical fibre diameter analyser. These analysers play a vital duty in the manufacturing, installment, and upkeep of optical Fibre cables, where precise measurements of Fibre Diameter significantly influence the overall performance of interaction systems

In telecommunications, maintaining consistency in Fibre Diameter is essential for decreasing signal loss and maximizing transmission quality. Variations in Diameter can cause raised depletion and minimized transmission capacity, influencing information transmission rates. Optical Fibre Diameter analysers make it possible for professionals to check and regulate these dimensions throughout the manufacturing process, ensuring that the fibers satisfy strict specifications.

Furthermore, throughout installment and maintenance, these devices aid in validating that the set up fibres conform to the called for requirements, thus preventing possible failures in communication framework. By utilizing optical Fibre Diameter analysers, telecommunications companies can boost their service integrity and client fulfillment.

High Quality Control Specifications

In the world of optical Fibre manufacturing, adherence to quality assurance criteria is paramount for making sure the home integrity and performance of interaction systems. The precision in optical Fibre Diameter is critical, as variations can significantly affect signal honesty and total system efficiency. Subsequently, manufacturers should carry out rigorous top quality control measures throughout the production process.

By sticking to well-known high quality control standards, suppliers not just enhance the performance of their optical fibres yet likewise make certain client satisfaction and trust fund. Ultimately, durable high quality control techniques are essential to the success of optical Fibre manufacturing and the advancement of communication technologies.

Future Trends in Dimension Innovation

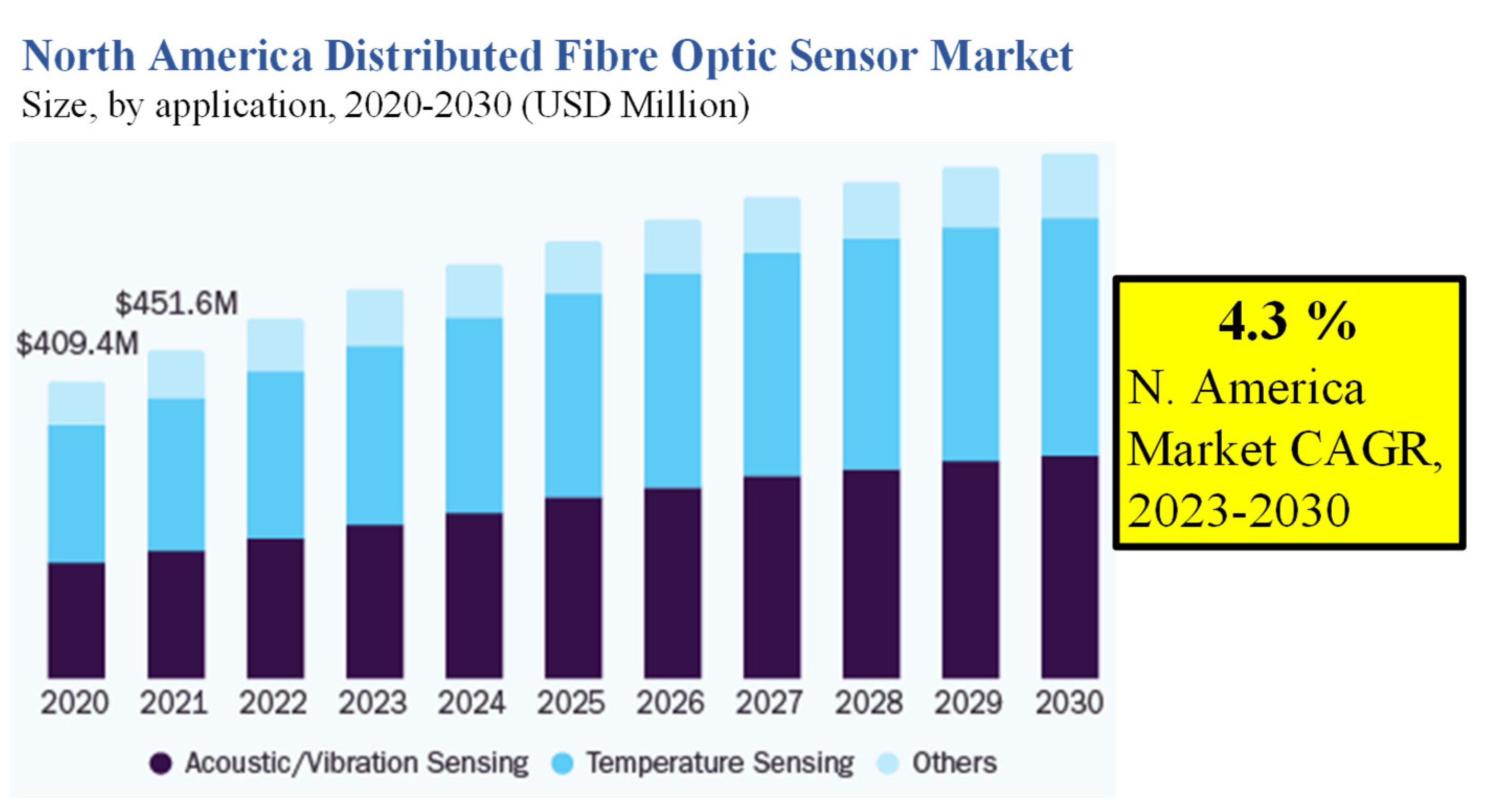

Just how will improvements in dimension modern technology shape the future of optical Fibre manufacturing? As the demand for high-performance optical fibers rises, accuracy dimension tools will end up being progressively important. Future trends indicate a shift in the direction of automated, high-throughput measurement systems that use advanced formulas and expert system to improve precision and effectiveness. By integrating real-time information and sophisticated sensing units analytics, makers will have the ability to check Fibre Diameter variants with unprecedented precision.

In addition, the unification of non-contact dimension methods, such as laser triangulation and optical comprehensibility tomography, will certainly lower the risk of contamination and physical damage to optical fibres throughout analysis. These advancements promise to simplify quality assurance procedures, making sure that just the most dependable items reach the marketplace.

Sustainability will certainly also play an important role in future measurement innovation. Energy-efficient systems and recyclable materials will certainly be focused on, straightening with international environmental criteria. In addition, the adoption of Industry 4.0 concepts will certainly promote seamless assimilation of dimension innovation within clever production ecological useful reference communities, allowing for constant enhancement more and rapid technology.

Conclusion

Finally, the optical Fibre Diameter analyser acts as an essential instrument for making certain precision in telecoms. Precise dimensions straight boost signal toughness and transmission high quality, therefore decreasing signal loss. These analysers not just support high quality control standards yet also foster customer confidence in optical Fibre modern technologies. As the electronic landscape remains to advance, developments in measurement modern technology will certainly better solidify the value of these analysers in maintaining ideal efficiency and reliability within the telecommunications industry.

The accuracy of optical Fibre measurements is vital in the telecommunications sector, where even the tiniest inconsistency in Diameter can lead to considerable signal degradation. An optical Fibre Diameter analyser offers as an essential device to guarantee these measurements are consistent and precise, therefore enhancing total system efficiency. As telecoms modern technology continues to advance, the requirement for reliable optical Fibre Diameter analysis becomes increasingly critical, highlighting the importance of employing sophisticated dimension devices and methods to maintain top notch communication networks.

Exact dimensions of optical Fibre Diameter are crucial for enhancing network performance and integrity. Optical Fibre Diameter analysers make it possible for service technicians to check and regulate these dimensions throughout the production process, guaranteeing that the fibers fulfill rigorous specifications.

Report this page